Fluorescence

Parts

- 4 3D printed filter cubes

- 1 3D printed V-Slot support

- 8 5" Hexagonal M8 Bolts, Nuts and Washers

- 4 8" Nylon Cable Straps Zip Ties Wire

- 1 GT2 Timing Belt Closed-Loop 200mm

- 1 Mount Plate - NEMA 17 Stepper Motor

- 1 NEMA 17 Stepper Motor

- 4 SinkPAD-II 23mm Quad LED Modules

- 4 Thermal Adhesive Tape

- 4 Thorlabs Fluorescence Imaging Filters Kit

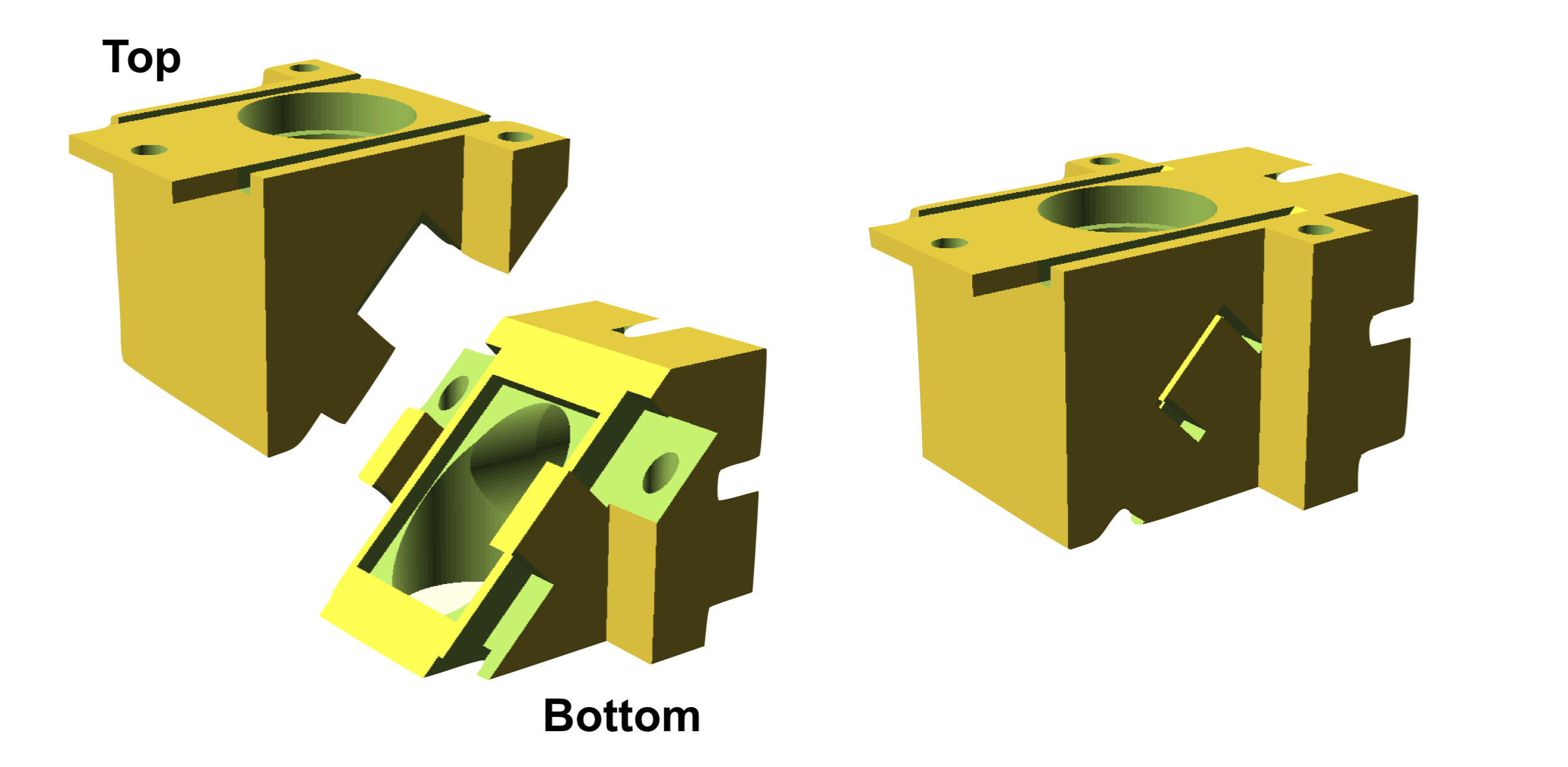

Step 1: Print filter cubes

- The fluorescent excitation module is based on 3D printed filter cubes. Each filter cube is composed of two parts:

Download STL/baffle_filterCube_top.stl

Download STL/baffle_filterCube_bottom.stl

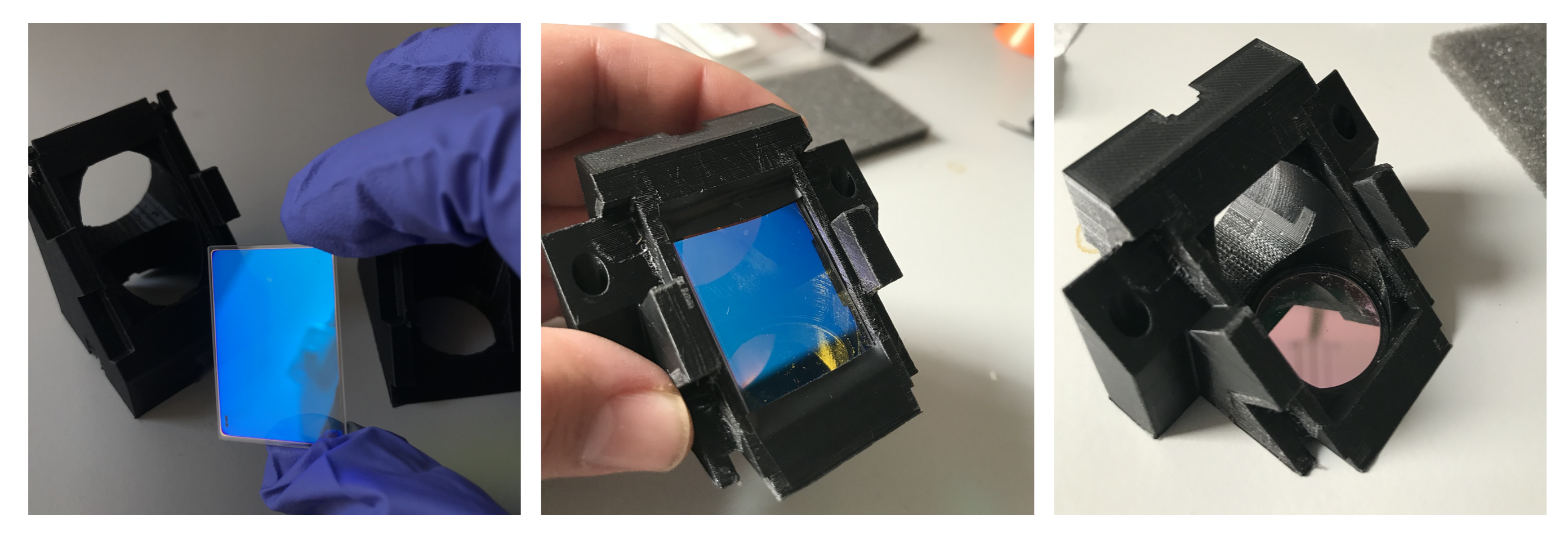

Step 2: Filter cube assembly

- Each one of the four cubes holds a Thorlabs Fluorescence Imaging Filters Kit consisting on excitation and emission filters, as well as a dichroic mirror. In particular, we use the following setup (excitation/emission wave-length):

Red (559nm / 630nm) for RFP

Green (469nm / 525nm) for GFP

Cyan (434nm / 479nm) for CFP

Yellow (497nm / 535nm) for YFP

- For each cube, attach the excitation filter in the lateral part, and the emission filter in the top side. The dichroic mirror is placed between both parts, at a 45 degree angle.

Note

Filters and the dichroic mirror have orientation (etched corner indicates dichroic-coated side). Make sure they are placed in the right position.

Step 3: Attach high intensity LEDs

- The fluorescent illumination consists in SinkPAD-II 23mm Quad LED Modules with specific wave-lengths that depend on the fluorescence setup. In particular, we use the following colors:

Red (627nm) for RFP

Blue (470nm) for GFP

Cyan (505nm) for CFP

Amber (590nm) for YFP

- Apply solder dots to connect the Quad LEDs in serial (as illustrated by the red circles below):

-

Attach the module to the LED Heat Sink using Thermal Adhesive Tape for 23 mm Quad LED Assemblies.

-

Attach each LED module to their corresponding filter cubes using 8" Nylon Cable Straps Zip Ties Wire

-

Connect all modules to the BuckPuck DC LED Driver.

Step 4: Cut acrylic discs

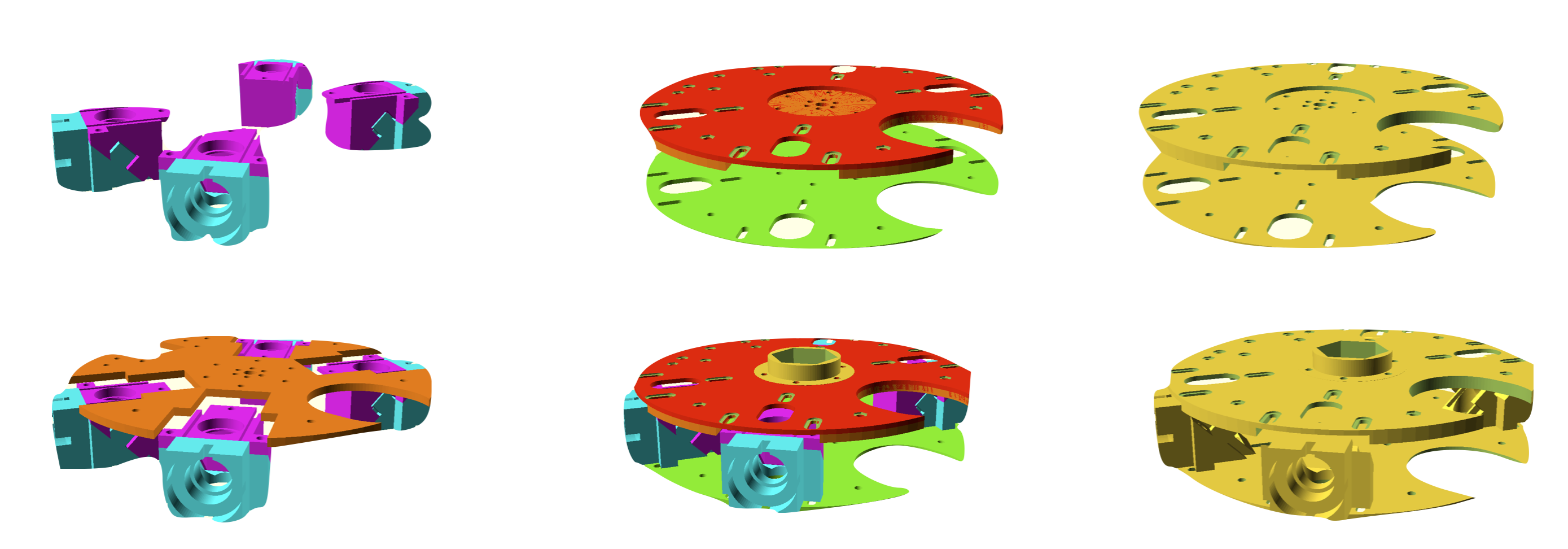

- The filter wheel holds all four fluorescence cubes equally spaced together with a hole and consists of three 5mm acrylic discs cut using the following SVG files:

Download SVG/filter_wheel_support_disc1.svg

Download SVG/filter_wheel_support_disc2.svg

Download SVG/filter_wheel_support_disc3.svg

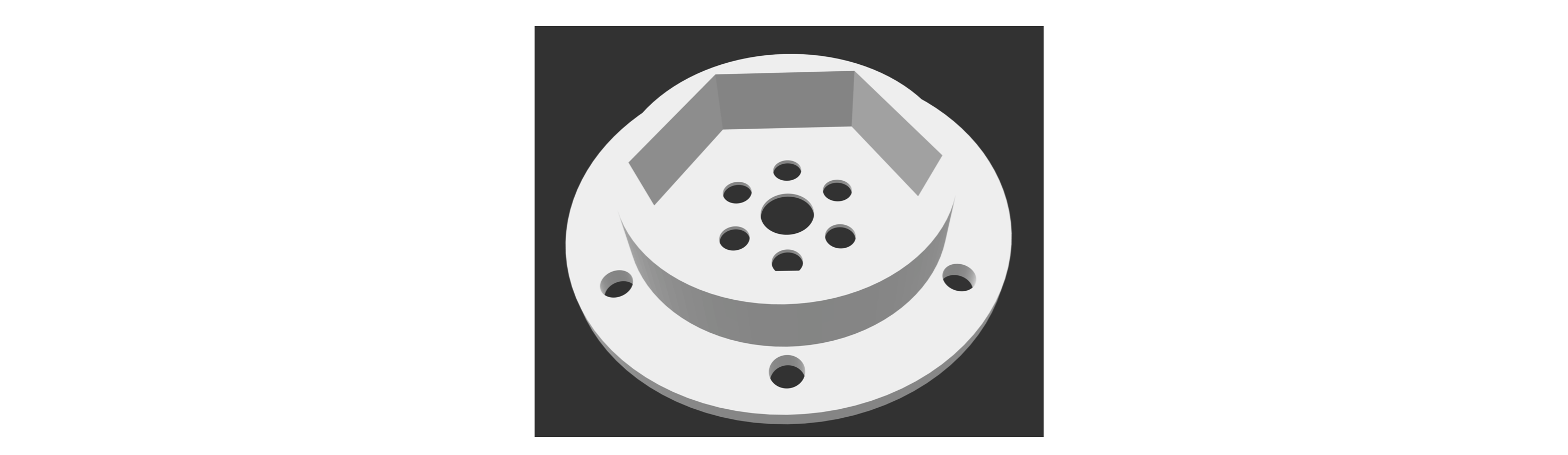

Step 5: 3D Print filter wheel shaft

- Download and print the following part:

Step 6: Filter wheel assembly

- The filter wheel holds all four fluorescence cubes equally spaced. To assemble the filter wheel, position all four filter cubes and attach to the the discs using 5" Hexagonal M8 Bolts, Nuts and Washers as illustrated below:

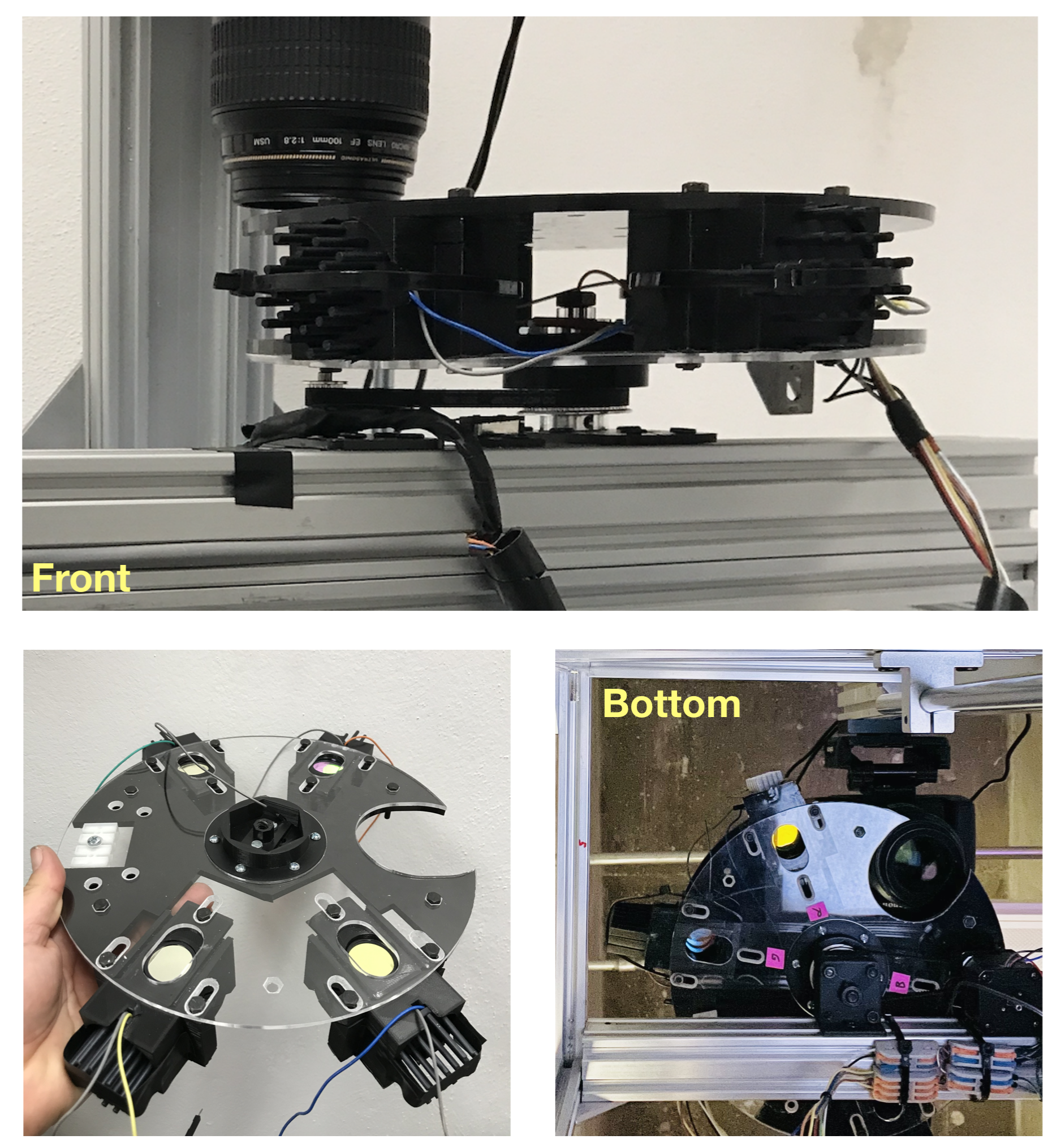

Step 7: Mount filter wheel in main frame

- To attach the filter wheel to the V-slot, we use a 3D printed V-Slot support:

Download STL/filter_wheel_shaft_bottom.stl

Download STL/filter_wheel_shaft_top.stl

Download STL/filter_wheel_shaft_spacer.stl

-

To rotate the filter around its central axis, we couple the filter wheel to a Nema17 stepper motor using a GT2 Timing Belt Closed-Loop 200mm.

-

Attach the NEMA 17 Stepper Motor to the horizontal V-Slot using a Mount Plate - NEMA 17 Stepper Motor. Do not tighten the screws yet as they will need to be adjusted.